YEARS AGO, NATIONAL Optronics was the first to come out with a dry cut edger that didn’t need water, which was significant when polycarbonate came on the scene, says Rick Duggins of 20/20 Vision in Indiana, who’s been in the finishing business a long time. “They used to have edgers that used patterns; now they’re all pattern-less, which makes it easier for us,” he adds. In The Vision Council’s 2022 survey of 1,174 U.S. ECPs, 44% of respondents said that their practice offered in-office surfacing/edging with responses coming primarily from independent practices. These days, finishing equipment is more user intuitive, faster, and more accurate.

Visionix

Briot Couture is an intuitive lens finishing system suitable for any optical store. It uses a virtual 3D lens rendering technology to simplify the process.

(800) 729-1959 | visionix.com

Essilor Instruments USA

The Pro-E 700 edging system can process even the most complex jobs efficiently. Advanced features include engraving, Oakley Half Jacket wraps, Chemistrie clips, safety beveling, super chamfering and creative shapes.

(855) 393-4647 | essilorinstrumentsusa.com

MEI System

EasyFit Trend is a block-less compact edger with the high precision and reliability of milling technology, eco-friendly Dry Cut technology, and a “No Block” system that eliminates blocks and pads.

(630) 521 8588 | meisystem.com

Coburn Technologies

The HAB-910 Exxpert automatic lens tracer/blocker is part of its 910 line of finishing products. It includes lens recognition, a camera, lensmeter, fast

power reading and quick tracing.

(800) 262-8761 | coburntechnologies.com

Advertisement

DAC Technologies

National Optronics’ 7Ex edger allows precise drilling and grooving. It can process all bevel types and edge high base lenses and complex shapes using a unique cutter design.

(800) 800-1550 | dactechnologies.com

Advancing Eyecare

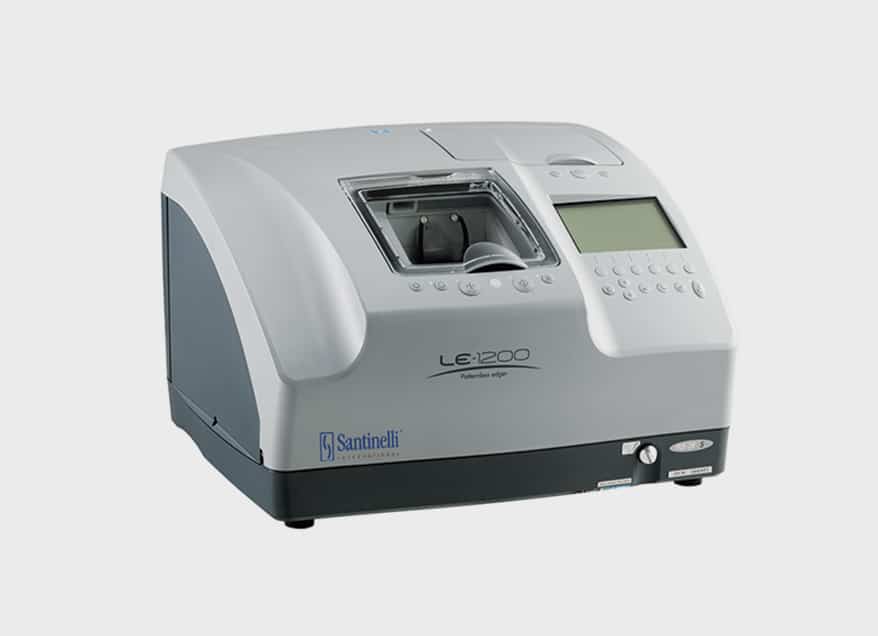

Their most popular model is the Santinelli LE-1200 patternless edger.

(855) 777-2020 | advancingeyecare.com

Smart Ways to Use In-House Finishing Equipment

Gregory Breaux, ODToday’s Vision, Conroe, TX

We strive to offer a personal, patient-centric experience from when we book appointments, to … offering them an in-house finishing service. This means we can control the quality of our product and tell patients their glasses will be ready in 20 minutes. We start the conversation in the back when I complete an exam. I talk about products I believe in like a certain brand of progressives or DuraVision coatings and go over insurance. I believe this differentiates us from our big box competitors. Sometimes I’ll make up the lens or my lab tech will do it. If it’s a single vision job, we’ll verify we have a premium blank in stock. Our intelligent blocker and edger from Santinelli are so accurate and user-friendly, we can train an optician on them in a short amount of time. Having our own lab helps our bottom line. By offering a same day service to patients, they don’t mind paying for add-ons like AR coatings.

Rick Duggins20/20 Vision, Kokomo, IN

I’ve been using National Optronics’ edgers for about 45 years. They are real workhorses. I use two now, the Horizon ll to edge down a thick lens, and the 7Ex which I bought three years ago. I have the National Optronics’ edger, tracer (which holds 100 jobs in the memory) and a blocker. We probably run 12-18 jobs a day on the 7Ex. We make fewer flat-tops now as most people wear progressives. We can make glasses on the spot; I made four pairs yesterday for people who needed them immediately. In 1988, surfacing and finishing in-house was the thing to do. If I was starting today, I don’t know if I would do it. Insurers like EyeMed, VSP, Spectera and Davis all want to make their own lenses and pay us a dispensing fee which cuts into our revenue.