FINISHING JOBS IN-HOUSE can be a real bonus for many eyecare professionals. Even though there’s an initial upfront cost to buying a machine, savings can be realized soon thereafter. According to The Vision Council, about 53 percent of all ECP locations have some type of finishing equipment on-site with a further 20 percent owning a surfacing system. There are certainly many efficient and reliable machines to choose from since most manufacturers include retail edgers in their line of lens finishing systems.

Luneau Technology USA

Briot Perception 2, Briot Attitude, WECO E.3/2

(800) 729-1959, luneautech.com

Optek International

E1000-GP Edger, FD-80 Tracer, LS-82 Blocker, DM-1000 Lens Drill, Dia E1000-E920

(727) 522-2301, optekinternational.com

MEI System

EzFit No Block

(630) 521 8588 | meisystem.com

Advertisement

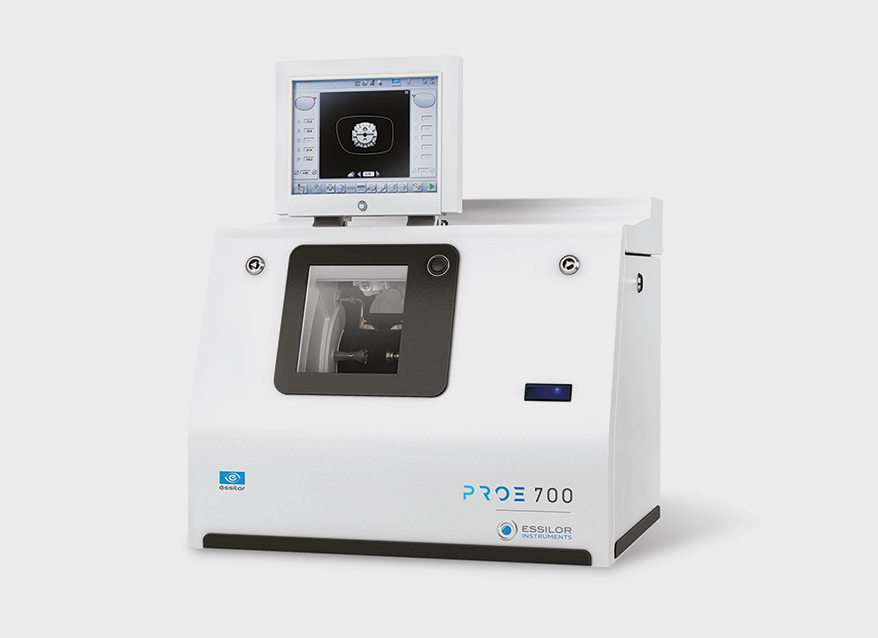

Essilor Instruments USA

Pro-E 700 edging system, KAPPA, Special Edition edger

(855) 393-4647 | essilorinstrumentsusa.com

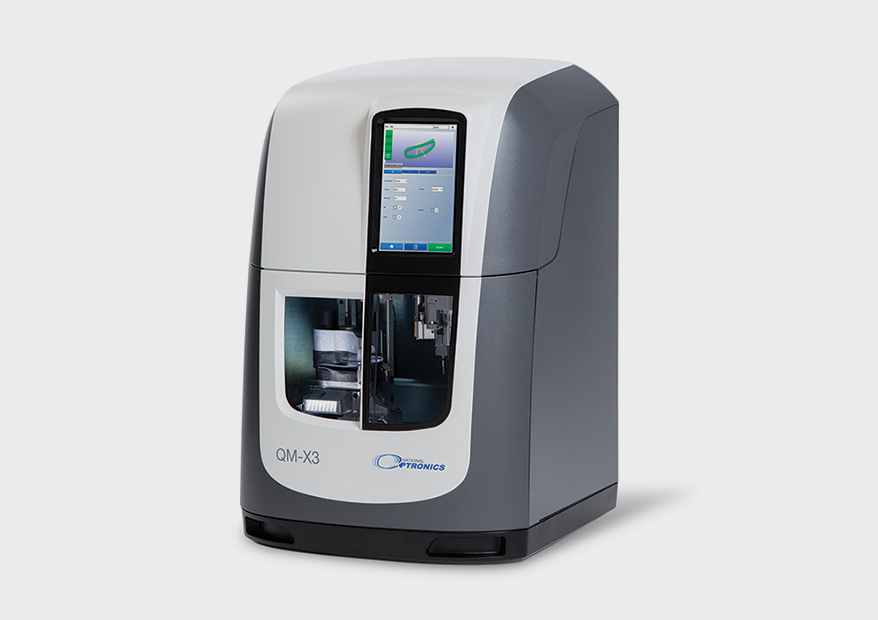

National Optronics

17Ex Edger, QM-X3

(800) 800-1550 | nationaloptronics.com

Santinelli International

Me 1200, Lex 1200, LEXCE, Le 1200, Le 700

(800) 644-3343 | santinelli.com

Advertisement

Coburn Technologies

Excelon HPE-410, Exxpert HPE 8000X, HPE-810

(800) 262-8761 | coburntechnologies.com

Smart Ways To Sell In-House Edging

Penn Moody, OD, MOODY EYES, INDIANAPOLIS, IN

In 2011, we decided to add an edging lab for better control over expenses and quality. At Vision Expo we chose the DIA from Optek. We’ve been very pleased with this choice. The vertical orientation allows the pressure on the lens to be adjusted during edging. We purchased a second DIA in 2017. We now process over 80 percent of our glasses, which has added substantially to our profitability and patient satisfaction.

Wendy Salle, SALLE OPTICIANS, ATLANTA, GA

We’ve been edging in-house for the past 30 years. I had to put in a second machine this year because of the volume. We’re up to about 25 jobs a day on two Santinelli machines, the Me1200 and the LEXCE. We do a lot of custom rimless work which can take an inordinate amount of time. But, it’s hard to find a lab that does good finish work and it’s a no-brainer for me to do it in-house. I don’t look at cost savings but I do look at being able to have ultimate control over our products.

Ronald Garbatini, ROYAL VISION ASSOCIATES NEW HAVEN, CT

We were spending between $8,000-$10,000 a month in lab bills before we got the Briot Attitude in 2016. Now we’ve cut that in half. Even though it’s an expensive machine, it’s paid for itself already. We edge about 30-50 jobs a day through this machine: everything from poly to plastic, high index, single vision, progressives to flat top bifocals. Patients like that we do jobs in-house, especially if they use private insurance.