THE PROS AND CONS of having an in-house lab depend on where you’re standing. Where some ECPs see an expensive headache — which someone else can handle anyway — others see a money-saving customer-winner that’s actually a lot of fun. The size and shape of your market, your personal and professional priorities, your comfort with gadgetry and the age of your business all factor in. As should recent changes in the industry, in particular the nature of distribution, evolving lens technologies and shifting consumer behaviors. If you’re a one-woman or –man operation, it’s probably not for you. Some folks have plenty of manpower but find that having a lab makes employee management a little bit too complicated. For others, it’s a case of “let labs be labs, let opticals sell eyewear.” So much for the cons: When it comes to the pros, we decided to ask around. Here’s what ECPs with successful in-house labs had to tell us.

Sonoma Eyeworks Santa Rosa, Ca

Cindy Harmon at Sonoma Eyeworks in Santa Rosa, CA boils the pluses of having an in-office lab down to three things: It allows you to provide exceptional customer service; it differentiates you from other practices; and it serves as a business builder. Her full-time manager, Wayne Wilmsen, has greater quality control on one-of-a-kind frames, custom drill mounts, and “does so much more than just edge lenses,” she says. As an extra bonus, “Our lab is somewhat visible, so it allows customers to witness the complexity of fabricating eyewear. It’s very easy to discount the reasons for investing in laboratory technology and the additional staffing. We’ve always felt it is one of the silent partners in our success.”

D’ambrosio Eye Care Lancaster, Ma

“I love it,” says Jocelyn Mylott of the in-house lab at D’Ambrosio Eye Care in Lancaster, MA. “I wish more managed care would allow us to edge in-house; saves so much time for the patient.” Quality is a key factor in in-house edging at D’Ambrosio, which now has five locations but made the decision to set up a lab with the launch of the third office. The sheer volume of orders warranted the move, Mylott says, given the cost of edging, shipping the frames back and forth and time lost during that process. “Per job it’s cost effective to edge in-house and you save the job turn time two or three days. Money and time make it worthwhile,” she says. Other advantages include the stock lens costs, which are lower. Considering the cost of digital progressive lenses nowadays, any cost saving you can squeeze out on single vision is to be grabbed, she says. “We can also use our stock lenses to provide promotions to patients at a more affordable price.” The lab now serves as a central ordering hub, with a courier driving between the five locations. All orders originate from the opticians. Those that D’Ambrosio’s lab can handle are taken care of in-house. Orders that need to be sent out are submitted by the lab staff, which reduces employee errors. “All product is drop-shipped to the lab, centralizing receiving and invoicing. We also offer patients who cannot be without their frame an option to wait for their order while we finish their new lenses.”

Cherry Optometry Chelsea, Mi

“I love my Santinelli!” confesses Paula Koch, OD, at Cherry Optometry in Chelsea, MI. She decided to get an edger to increase turnaround on jobs, and quickly discovered that edging is not only satisfying and fun, but lends a personal dimension to the transaction. “Patients love glasses done quickly — I think of it as ‘Amazon Prime’ for eyeglasses. And they like the personal attention they get with me making their glasses.” When a patient comes in with a broken frame, there’s something deeply satisfying for us both about being able to cut them into another frame right then and there. “Talk about a ‘WOW!’ Patients are thrilled.” Koch’s Santinelli rep, Jaysun Barr, invited her to join the Opening Eyes program, which provides exams and makes glasses for Special Olympians. Her son comes in to help cut the lenses for the program. “It’s a little thing but it allows me to keep my kids involved in the business.”

Alberta Eye Care Portland, Or

The motivation for Alberta Eye Care’s purchase of an edger (they now have one in both offices) was long-term cost savings. By buying stock lenses in bulk, explains co-owner James Armstrong, they saw significant savings on their cost of goods, allowing them to offer competitive pricing and faster turnaround. But a second benefit emerged: quality control. Armstrong finds that jobs edged by his opticians have fewer errors than those from an outside lab. Lastly, “Without our lab, we would not be able to afford to continue working with children in the Oregon Medicaid program.” Alberta stocks Trivex and 1.67 with AR, which Armstrong says saves money and reduces delays related to lab edging.

Dr. Bladh, OD Diamond Bar, Ca

Far from being a cool option, at Dr. Bladh OD in Diamond Bar, CA, a lab is viewed as a necessity. They’ve had their edger for nearly 20 years, and repeat patients know their Rx is usually in stock. The original aim was to provide quicker turnaround time; in the beginning they were lucky if their lab could get glasses back in two weeks. “Back in the day,” says Josh Bladh, “edgers required patterns, if anybody remembers that. We purchased a patternless edger when they came out and it changed our lives… we were able to have the job done in less than a week and when retail chains started to say glasses in an hour or less, it wasn’t a novel idea for our patients.” Bladh summarizes the main benefits as differentiation from non-lab practices and “being able to under-promise and over-deliver” -— staff tell patients their glasses will be ready in 7-10 working days, just in case, “But we know full well that if the lens is in stock we might be able to have that job done in less than an hour. We love exceeding patient expectations!” The practice only stocks CR-39 and Polycarbonate single vision lenses. They stock slightly higher powers than “normal” parameters, but anything with Transitions or AR coating they order. Those typically only take a couple days to get in, and the office usually has someone who knows how to cut lenses in five days a week. “A lot of our second pair $99 special deals get cut before the nice expensive pair because they’re just looking for a basic pair as a backup.”

Advertisement

EYEcare Plus antioch, tn

When Kevin Schmidt, OD, launched his practice, he provided most of the glasses out of his own lab. That changed after a while, but with recent industry developments bringing a higher percentage of antireflective coating and new digital designs requiring even more outside lab use, “I had to decide again to be in the lab business. Financially it has increased my AR percentage to numbers I never thought possible.” Schmidt has been able to add digital design, while still providing it as an upgrade to pay for the new equipment. “Turnaround time is unbelievable and patients are even happy occasionally with the great service,” he jokes. Running a seven-location practice, he’s taken some extra tech on board, using a robotic edger to return lenses to the other six locations; they only have to be inserted into the frame. “Schneider Box AR coating and two digital generators in a practice our size is unique, and sputter mirror coating has enabled us to do almost any Rx in house,” he says.

Optical Alternatives Milford, Ct

Optical Alternatives in Milford, CT, has edged in-house since it opened, says Dorothy Reynolds. They stock single vision with AR and find that being able to tell customers they can have their glasses that day helps make a sale. And there’s a feel-good factor in being able to provide single vision lenses if someone has broken their glasses, especially when in Milford visiting family. “It allows patients to use their own frame without having to give that frame up for a week,” she points out. Besides which, “It gives children a thrill, and some adults too, to see their glasses lenses being ‘made.”

Casa De Oro Eyecare Spring Valley, Ca

Jeff Grosekemper recalls how the doctor at Casa De Oro Eyecare in Spring Valley, CA, wanted to install edging equipment to save money; they found many insurance companies would let them do in-house edging — mostly single vision but some were OK with multifocals too. “Uncuts cost less in the long run — less labor cost so the equipment will pay for itself over time, and then create profit.” Grosekemper can cut stock lenses in-house in 15 minutes, which appeals to patients. Also, uncut lens orders arrive quicker, which allows him to cut down overall wait time by a few days. “Plus, I know it will be done right the first time,” he says with a laugh. As for the lab itself: “Love it. Gives me something different to do. We’re a small office so I do pretesting, sales, dispensing, repairs, billing, etc. It’s fun to escape to the lab and make lenses. Having the in-house lab lets patients know that we are fully equipped to handle little emergencies and everyday problems that come with wearing glasses.”

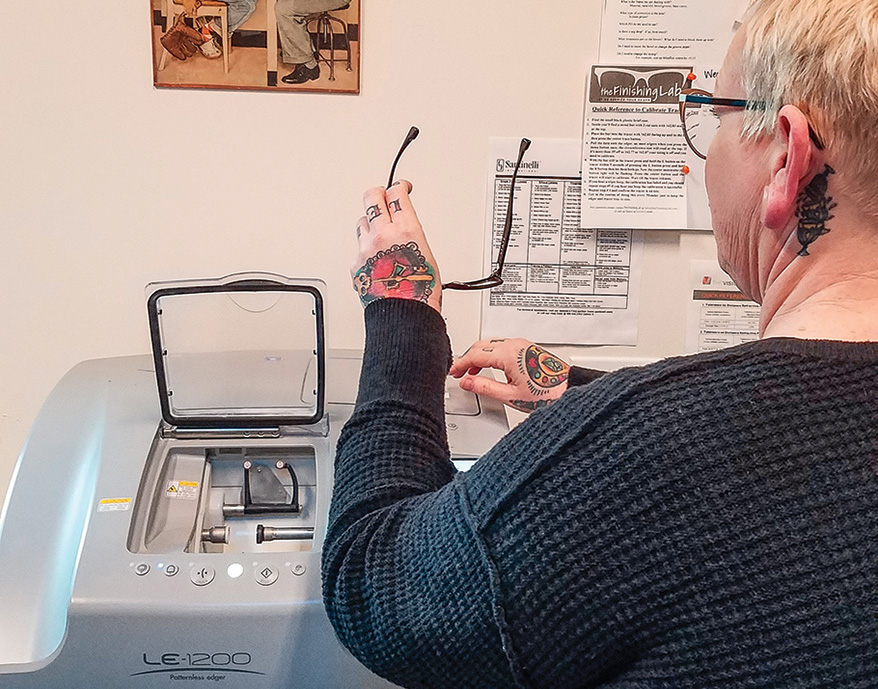

Eye Can See Eyewear Mcdonough, Ga

Being able to provide badly needed in-house finishing-lab services to the two small communities it serves is a huge advantage for Eye Can See Eyewear in McDonough, GA, says practice manager William Chancellor. So much so, in fact, that they have one at each location. “We can say, ‘I can have those glasses ready for you today.’ The surprise that we have that ability is a great value in itself!” The cost reduction of not having to use an outside lab keeps a lot of money in house and that is passed on to the employees. Eye Can See carries a good assortment of power ranges in single vision CR39 and single vision Polycarbonate with AR. “Ninety-plus percent of our orders are edged in-house, saving our practice thousands of dollars a year in edging fees. It truly warms our hearts to see a child be able to receive glasses for the first time the same day and say our name…Eye Can See!” says Chancellor.